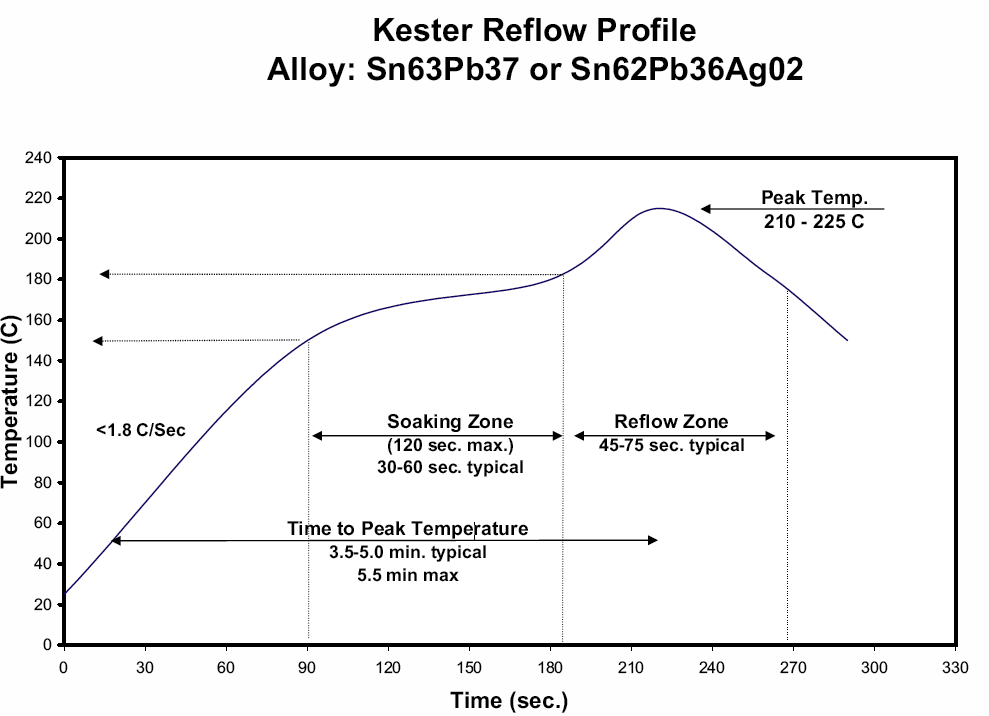

I need to know is there difference between oven and heatgun temperatures.

#Reflow oven temperature free#

All kinds of process parameters can be set on the operation screen, and can be switched with one button during production. Is 'Reflow Temperature' the same as 'Chip Removing Temperature' It says lead free solders melt at 250C. Vacuum + atmospheric process, vacuum + nitrogen process, atmospheric common process, nitrogen common process can be corresponding. The iron is at a much higher temperature than. split-type of flux recovery device can guarantee maintenance without halting. The temperature of a soldering iron does not resemble the temperature required for a solder joint to form.

#Reflow oven temperature professional#

Reflow oven design and manufacturing by professional team with more than 20 years experience, and important components from international famous brand, have ensured the high quality requirements of P series Vacuum Reflow Oven.Īccording to the characteristics of flux, set up multiple regions in the furnace for flux recovery mechanism, greatly improving flux recovery rate, reducing the maintenance time of the furnace. Super cooling performance can meet the requirements of a variety of Pb free solder, cooling speed can reach more than 8℃/ second. ▲ Soldering quality and reliability are improved greatly.ġ)Soldering void area ratio can be reduced to less than 1%.Ģ)Mechanical strength of solder joint is improved greatly.

As there is no track, and need to adjust width, it can completely solve the problem of deformation card plate of traditional reflow welded track and dead width adjustment.ģ)In the process of vacuum, the product is placed on the lower heating plate, and the substrate with high thermal conductivity can achieve the effect of rapid heating.

Application Fields Features 1.Furnace configuration 2.Specialityġ)The upper hot air heating solves the problem of the uneven temperature caused by contact heating of conventional high temperature reflow welding, and the thermal conduction issue of non-metallic substrates.Ģ)The lower part adopts high temperature heating plate, and the maximum temperature can be set at 450 degrees, which can meet the requirements of rapid heating of large thermal capacity power devices such as metal or ceramic substrate.ġ)It adopts the stepwise lifting and feeding method of jacking up - moving forward - dropping, and is driven by servomotor to ensure the smooth and no vibration of the product in the process of moving.Ģ)It can correspond to regular products of different widths from 100mm to 400mm.

0 kommentar(er)

0 kommentar(er)